Prototyping China: Elevating Your Business with Metal Fabrication

The world of business is continuously evolving, with innovative techniques and methodologies shaping how products are developed and manufactured. Among these, prototyping in China has emerged as a leading trend that offers both efficiency and cost-effectiveness. This article delves into the dynamics of prototyping in China, specifically highlighting the role that metal fabricators play in transforming ideas into tangible products.

Understanding Prototyping in China

Prototyping is an essential step in the product development process, allowing businesses to test concepts, gather feedback, and refine designs before mass production. In recent years, China has become a hub for prototyping due to its robust manufacturing capabilities, skilled labor force, and advanced technologies. This allows businesses to iterate quickly and efficiently while keeping costs low.

Why Choose China for Prototyping?

The decision to engage in prototyping in China is influenced by several compelling factors:

- Cost Efficiency: China offers lower labor and material costs compared to many Western countries, making it an attractive destination for prototyping.

- Speed: The rapid turnaround times in Chinese factories allow companies to move from concept to prototype much faster.

- Access to Advanced Technology: China's manufacturing sector is equipped with state-of-the-art technology, enabling high-quality prototypes.

- Skilled Labor Force: A large pool of skilled workers, trained in modern manufacturing techniques, ensures quality and precision in prototyping.

The Role of Metal Fabricators in Prototyping

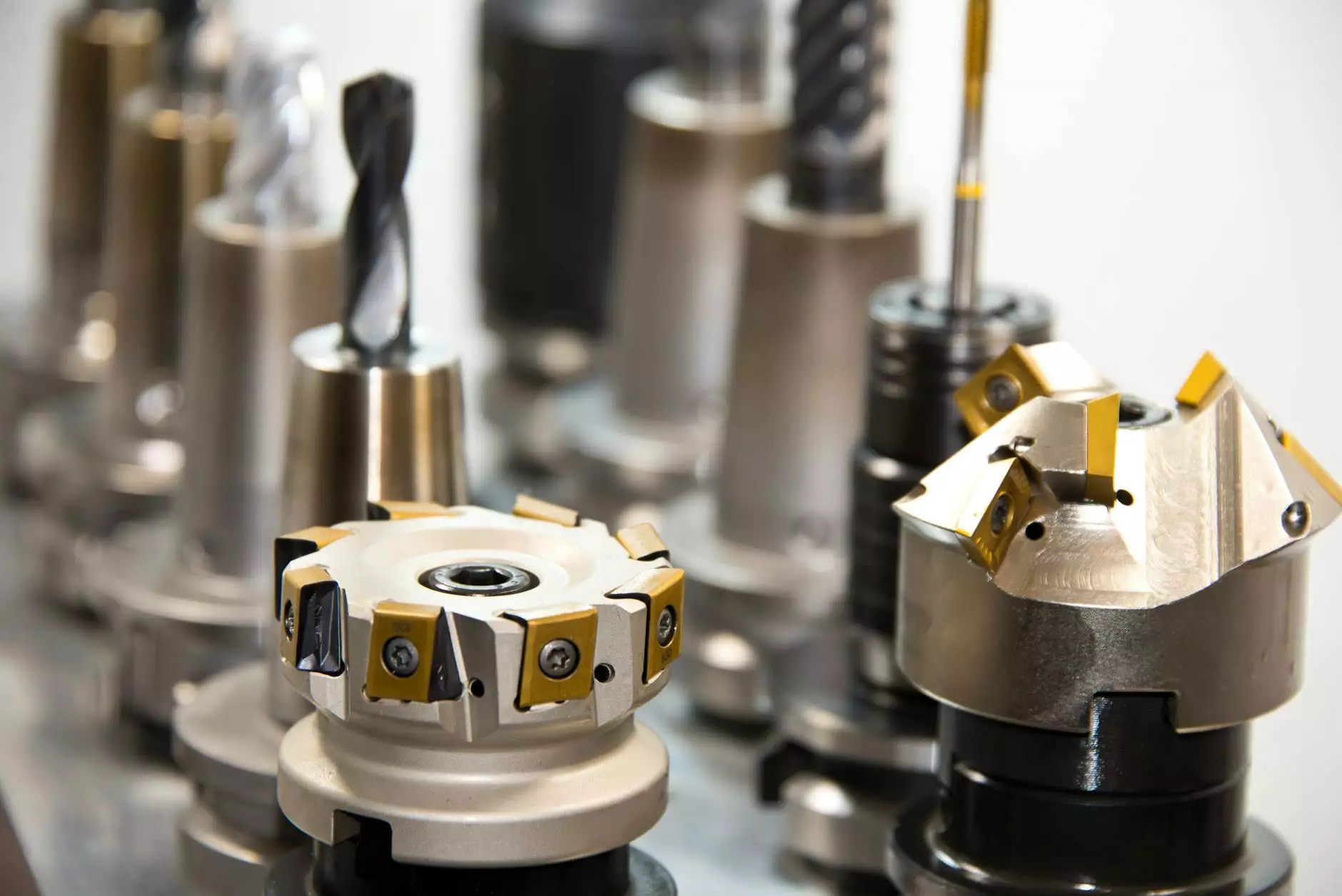

Metal fabrication is a critical component of many prototyping projects. It involves the process of building metal structures by cutting, bending, and assembling processes. Metal fabricators possess the expertise and technological resources necessary to turn raw materials into functional prototypes. Here’s how they contribute to the prototyping process:

1. Precision Manufacturing

With the capability of employing CNC machining, laser cutting, and advanced welding techniques, metal fabricators in China provide high precision in every project, ensuring that the prototypes meet exact specifications.

2. Material Diversity

Metal fabricators work with a multitude of materials, including steel, aluminum, brass, and titanium. This versatility allows businesses to choose the most suitable materials for their prototypes based on specific requirements such as durability, weight, and cost.

3. Customized Solutions

Every business has unique needs, and metal fabricators excel in creating customized solutions. They can adapt designs and processes to meet individual project specifications, ensuring that prototypes align with the client's vision.

Integrating Prototyping with Your Business Strategy

Incorporating prototyping in China into your business strategy can yield significant advantages. Here are some strategies to effectively leverage this process:

1. Develop a Clear Project Brief

Articulating what you want from the prototyping process is key. A detailed project brief helps both you and your metal fabricator understand the end goals, materials needed, timeline, and budget. This clarity significantly enhances the efficiency of the prototyping phase.

2. Foster Collaboration with Fabricators

Establishing a strong partnership with metal fabricators can lead to better outcomes. Their expertise in fabrication can provide valuable insights into the design process, helping you avoid potential pitfalls early on.

3. Utilize Feedback for Iteration

Once you receive the first prototypes, gather feedback from stakeholders, potential users, and team members. This information is crucial for making informed adjustments to the design before moving into full production.

Case Studies: Success Stories from Prototyping in China

Numerous companies have successfully implemented prototyping in China into their product development lifecycle. Here we showcase a few case studies to illustrate the tangible benefits:

1. Tech Startup: Rapid Gadget Development

A tech startup specializing in wearable devices partnered with a Chinese metal fabricator to create prototypes of their innovative products. By leveraging advanced prototyping techniques, they reduced their time to market by over 50%, leading to early sales and market penetration.

2. Automotive Industry: Precision Parts Production

An automotive company needed prototypes for new engine components. By utilizing China's metal fabrication capabilities, they achieved high precision manufacturing, leading to improved performance in their final product designs and significant cost savings in the prototyping stage.

3. Consumer Goods: Custom Design Variants

A consumer goods manufacturer created various prototypes for different design variants of their products through a Chinese fabrication partner. This not only provided them with varied options but also facilitated market testing at unprecedented speed.

The Future of Prototyping in China

As the landscape of global manufacturing evolves, prototyping in China is poised to adapt and innovate further. Emerging technologies such as 3D printing, artificial intelligence, and automation are set to reshape how prototypes are designed and fabricated. Companies looking to stay ahead must embrace these advancements, ensuring that their prototyping processes remain agile and responsive to market demands.

Conclusion: Transforming Ideas into Reality

In conclusion, the integration of prototyping in China into business operations not only enhances production efficiency but also fosters innovation. By leveraging the skills and technological advantages provided by skilled metal fabricators, companies can bring their ideas to life effectively and affordably.

For businesses ready to transition from concept to reality, engaging with a reputable metal fabricator like Deep Mould can be the catalyst for success in the competitive landscape of modern manufacturing.

prototyping china